Typically, resource and energy companies know they need to improve on asset management and maintenance. However, a lack of an integrated maintenance strategy – and the valuable ‘helicopter view’ such a strategy provides – leads inevitably to operational and safety risks, duplication, and inefficiency. The problem lies not in knowing there is room for improvement, but in how to get going.

- How do you resolve issues before they happen while balancing the cost of maintenance versus the cost of failure?

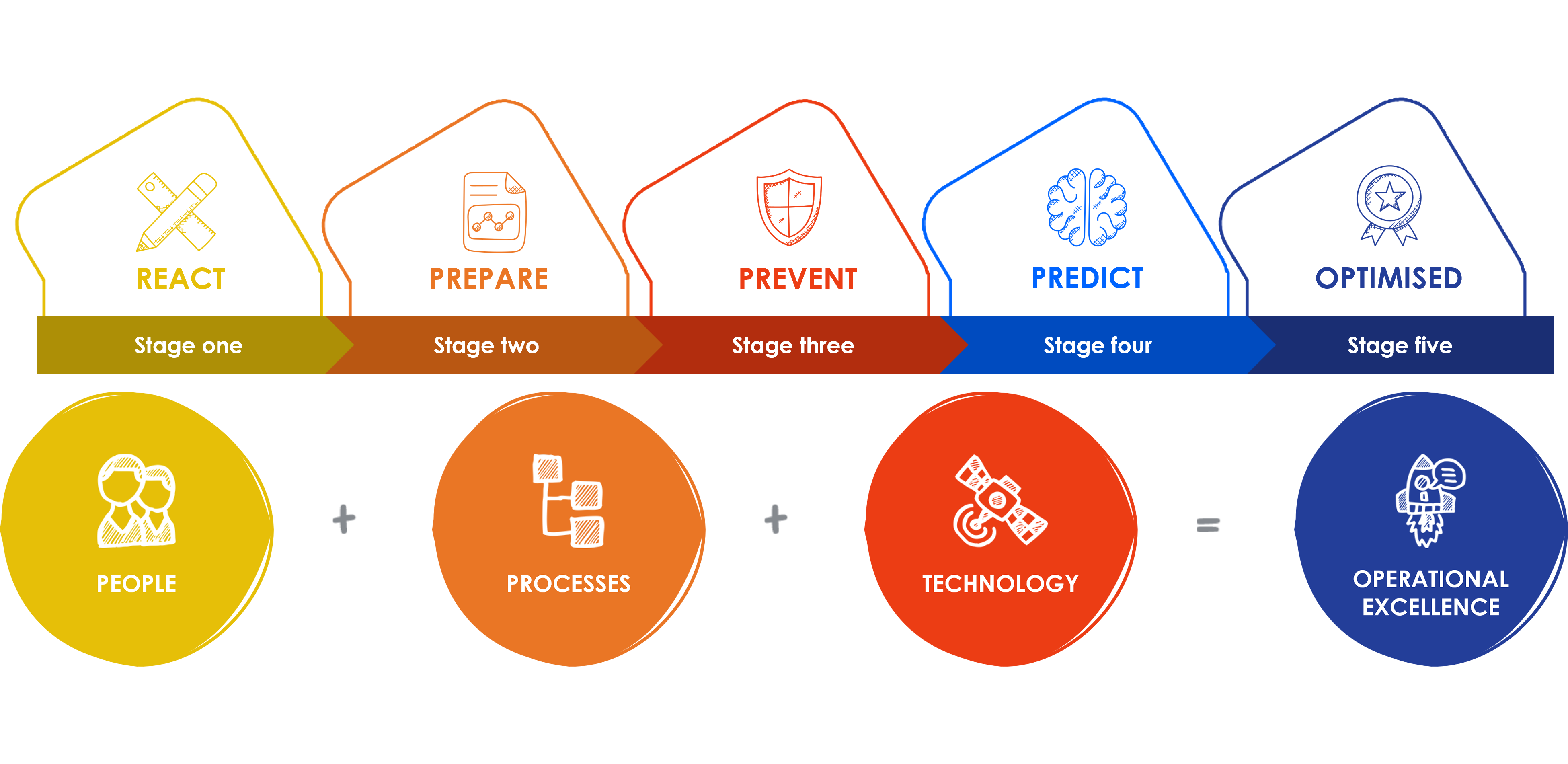

- How can you monitor your assets better, and move along the maturity curve from reactive to predictive maintenance or even optimised maintenance for operational excellence?

- How do you equip your team to maintain and repair your assets anytime, anywhere?

- How can you feed reliability data back to maintenance teams so that job plans, monitoring, maintenance schedules and strategies can all be improved?

Denver utilises a Capability Maturity Model to assess our clients’ current state of maturity; often benchmarking against other organisations of similar size and industry to provide recommendations for improvement. The goals is to move closer to an optimised state. The Capability Maturity Model below uses a "traffic light” system (red, orange, and green), aligned with the five levels of the CMM to assess Governance, People, Process and Technology within each process – (Procure an Asset, Register an Asset, Corrective Maintenance, and Preventative Maintenance) under each Asset Category.

With the right tool for the job and one that centralises processes with asset data, you can safeguard the asset, the processes it serves, the safety of people working with it and ultimately the financial reward generated from that investment. Optimising virtually all asset types brings cost-savings, efficiencies, asset reliability, extended lifecycle, and increased safety across the enterprise.

Whether it’s maintenance, reliability or asset management - Denver helps you get your maintenance strategies right and assists in execution to deliver the desired outcome. Denver consultants are highly experienced in all processes, data, and integration aspects of asset management and maintenance. We’ve worked across the Resource and Energy sectors to help our clients optimise their asset capability and improve their maintenance and reliability while reducing costs and risk.

Challenges We See Right Now

- Strategic Planning – contractor management and moving along the maturity curve

- Making reliability an equal partner in the MRO triangle.

- How to incorporate IoT to augment the operational performance data captured from Assets

- The many financial implications of Capital vs. Operational Expenditure is impacting maintenance strategies

- Increased focus on decarbonisation, environmental footprints and energy implications

- Companies don’t see their data as an Asset which needs to be cleansed, maintained and managed

- Asset Cost of Ownership and Asset Lifecyle management is often overlooked, but has a direct impact on the financial bottom line

- Knowledge walking out the door with aging, changing & reduced workforce

- Establishing and maintaining compliance & governance roles and processes

- Keeping the costs of maintenance & shutdowns within budget and time allocations

- Balancing the cost of maintenance against the cost of failure

- Developing and working to a consistent maintenance cycle

- Running effective end-of-day processes - capturing data about a maintenance failure, how the organisation fixed it and the associated cost

- Implementing scheduling that optimises the use of labour, plant, equipment and materials

- Moving from strategy to execution – how do you deliver on the recommendations of the strategy?

How We Can Help

- Strategy - Creating asset strategy & roadmaps; undertaking maintenance & reliability process reviews; working through OT Asset Management and lifecycle planning. Reviewing organisational structure - including people and skills to support maintenance strategy; business processes – including policy and procedures relating to maintenance

- Taking/creating a maintenance strategy and roadmap items/priorities from assessments and building policy frameworks for implementation.

- Architectural Landscape

- Maintenance, Reliability, Operations (MRO)

- Mobility

- Data and Integration - assessing, reviewing, implementing, and integrating relevant technology and data

Business Critical Asset Management Upgrade for BP

BP operates the BP-Husky refinery at Toledo in the United States in a joint venture with Husky Energy. The refinery processes up to 160,000 barrels of crude oil per day and provides the Midwestern United States with gasoline, diesel, jet fuel, propane and asphalt.

If You Can't Kick It, It's Not There

Do you have the asset visibility and data availability needed in your supply chain? In this article, we take the Maintenance Planner's perspective and discuss the importance of data in Resources and Energy supply chains.

Asset Management & Reliability: What is the math telling you?

Asset maintenance plans shouldn’t be set and forgotten; Given that assets' health directly impacts shutdowns, turnaround scheduling and resourcing, continual asset optimisation is incredibly important - even if everything appears to be working well.